Technical Office: Design and Programming

Our technical office has qualified and experienced professionals who can develop any type of project and produce the plans that they require. We utilise CAD and CAD-CAM programming to support CNC machinery.

The continuous training of our staff provides us with the know-how for manufacturing both our own parts and manufacturing tools.

Machining

We have a 1100m2 warehouse exclusively devoted to parts machining in short to mid-length series using CNC and conventional machinery.

CNC Section

5 Axis CNC Centres

RTT 5 Axis

MIKRON MILL E 700 U Machining Centre with numeric control

Sprint in 700x600x500 mm.

Tilt axes: -65 / +120

Rotation axes: n x 360

Axes: 3+2

Control Heidenhain Itnc 530 HSCI FS

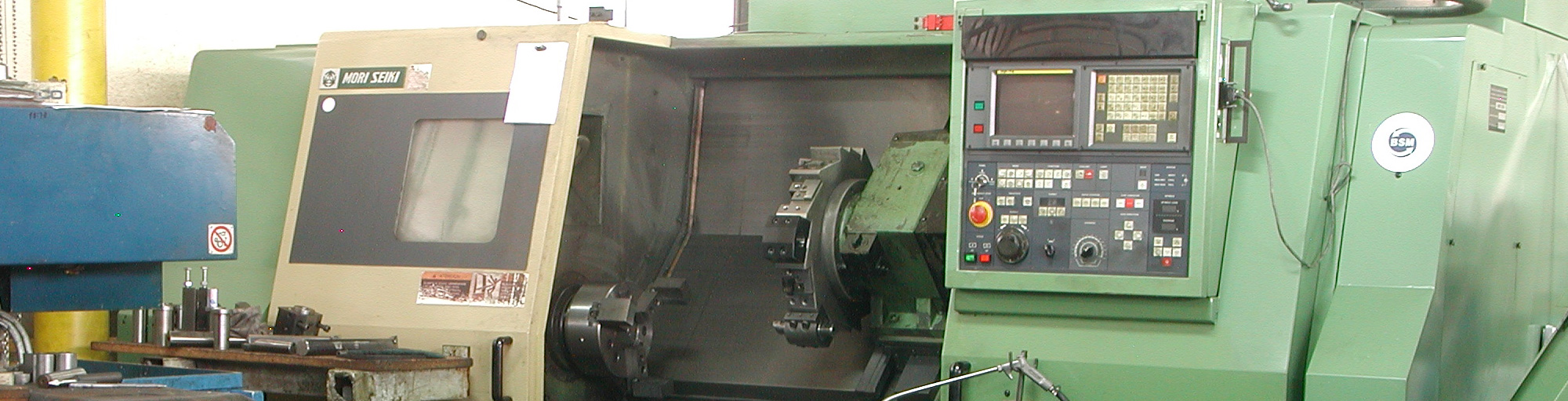

CNC Lathes

Daewoo Lathe Mod. Puma 8 S with FANUC numeric control

Swing 240 mm and part length in Z300

Doosan lathe. Puma 3100 XLY

Swing 420 mm and part length in Z2000

Doosan lathe. Puma 6 S with FANUC numeric control

Swing 200 mm and part length in Z400

Mori Seiki lathe Mod. SL.25 with FANUC numeric control

Swing 480 mm and part length in Z400

Mazak lathe Mod. QT Nexus 250 MSY II, dual-head bar and Y-axis

Swing 650 mm. Maximum machining length 541mm. 380mm cut diameter.

CNC centres

ANAYAK 7 Machining Centre with numeric control

Part size 800x500x505

Fanuc Control Mod. OT-M

Equipped with 4art SPIRSIN spindle

Machining ANAYAK 13 Machining Centre with numeric control

Part size 1300x560x560

Fanuc Control. Mod. OT-M

Fitted with a SPIRSIN 4th spindle

MORI SEIKI SV500 numeric control Machining Centre

Part length 1000x510x510

MSC-502 Control

MORI SEIKI SV400 numeric control Machining Centre

Part length 600x430x460

MSC-518 Control

Fitted with a NIKKEN 4th spindle

Interior cooling at 50bar

Machining Centre with numeric control

Part length 800x510x510

Fanuc MSG-501 Control

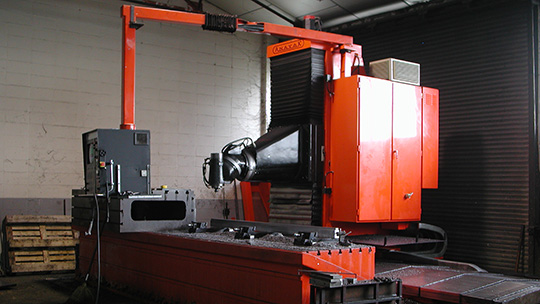

CNC milling machines

CNC NTE – BF 3200 milling machine

Equipped with CNC Heidenhain 530

X-axis stroke: 3000 mm.

Y-axis stroke: 1000 mm.

Z-axis stroke: 1000 mm.

ANAYAK milling machine with mobile column mod. HVM-5000.

Equipped with Heidenhain 415 CNC

Table surface area: 5000 x 1000 mm.

X-axis stroke: 4300 mm.

Y-axis stroke: 1200 mm.

Z-axis stroke: 1500 mm.

ANAYAK mod. VH-2200 milling machine. .

Equipped with CNC Heidenhain TNC 426

Automatic tool change.

Part size 2000x920x900.

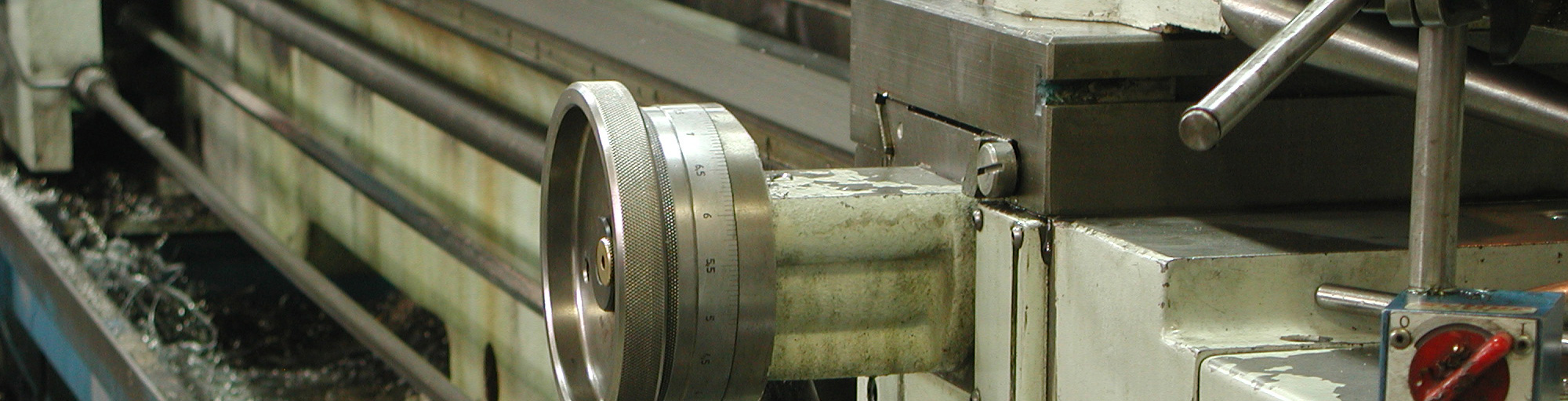

Conventional machinery section

Lathes

Pinacho Lathe Mod. S90/200

Swing 300 mm and part length in Z1500

Fagor display.

Pinacho Lathe Mod. S90/260

Swing 630 mm and part length in Z2220

Amutio Cazenev Lathe Mod. 575

Swing 525 mm and part length in Z700

Heidenhain display.

Trens Trencin Lathe Mod. SN630S

Swing 645 mm and part length in Z4000

Milling machines

3 FEXAC milling machines Mod. UM

Part size X940 Y260 Z350

Dimension display.

2 Fagor with Abs. and Incr.

1 Acurite-Vision prepared.

FEXAC milling machine Mod. UMS

Part size X940 Y260 Z400 W550

Hedainhein display.

CORREA Milling machine Mod. F2HA

Working part size X1100 Y250 Z450

Fagor display.

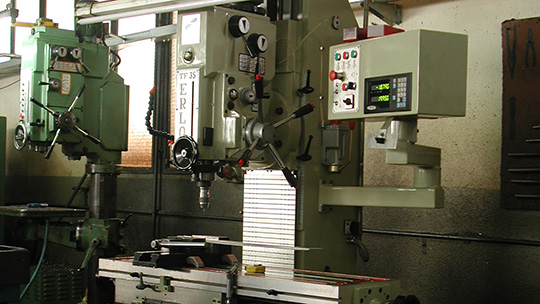

Borers

ERLO Borer-Milling machine Mod. SPV

Working part size X730 Y400 Z450

Fagor display.

2 ERLO Borers Mod. TCA-40

3 CMA Thread cutting machines-M4. Thread size capacity up to M30.

Cutting

Numeric automatic control cutting machine. MACC mod. 360

Capacity for a diameter of up to 160 mm

CNC DANOBAT cutting machine

Cutting capacity of up to 270 mm

2 FAT manual cutting machines. Mod. 270

Cutting capacity of up to diameter 270mm.

Cutting machine for Aluminium. MG

Mechanical Welding

In order to ensure the quality of our work, we have a specific department for the systematic control of our products. An area of 50m2 has been devoted solely to parts verification which is equipped with instruments that provide us with complete quality assurance.

Our measurement and calibration tools are certified by external laboratories and agencies recognised by ENAC (Spanish National Accreditation Body).

In 2011, the company implemented the ISO 9001 quality system, a standard that provides us with an integrated management system to ensure the quality of our products and the ongoing improvement of our organisation.

Welding Section

Welding machine

Invertec Lincoln Mod. 200-T

TIG and electrode welder.

Invertec Rehm Mod. 260 AC/DC

For welding aluminium and stainless steel.

Mig/Mag (wire) Lincoln Mod. 400-I

Performance power of 60% at 400 Amp. and 34 v.

2 Mig/Mag (wire) CEM Mod. Compact -31

Performance power of 60% at 240 Amp. and 26 v.

Mig/Mag (wire) Rehm Mod. Synergic 304

Performance power of 60% at 300 Amp. and 29 v.

Mig/Mag (wire) Rehm Mod. 400-I

Performance power of 80% at 300 Amp.

Mig/Mag (pulsed arc) Solter Inverter Mig

Performance power of 80% at 300 Amp.

Mig/Mag (wire) Solter Synergic 510

Performance power of 80% at 450 Amp.

Portable welder with large bottles and cutting nozzle.

Sheet Metal Section

Sheet Metal

DURMA 3 m/120 Tn Folding Machine.

Iron sheet of up to 5 mm.

DURMA 3m shears.

Metal sheet of up to 5 mm and 3 mm in stainless steel.

Testing and Quality Control

In order to ensure the quality of our work, we have a specific department for the systematic control of our products. An area of 50m2 has been devoted solely to parts verification which is equipped with instruments that provide us with complete quality assurance.

Our measurement and calibration tools are certified by external laboratories and agencies recognised by ENAC (Spanish National Accreditation Body).

In 2011, the company implemented the ISO 9001 quality system, a standard that provides us with an integrated management system to ensure the quality of our products and the ongoing improvement of our organisation.

Our quality policy encompasses all the company’s operations, enabling us to ensure the quality of our products and services, deliver products that meet our customers’ requirements and comply with the applicable regulations, as well as establishing a company strategy in keeping with the context of Tecnomecánicas SHINE SL.

Assembly

500m2 of our premises is specifically devoted to the assembly of units and sub-assemblies, as well as machines and their parts.

The Tecnoshine team is highly trained in order to ensure the best results in machine and part assembly procedures.

Polígon Industrial de Puigtió - Apartat de correus 118 - 17412 Maçanet de la Selva (Girona, Espanya)

Fax: 972 859 106

info@tecnoshine.com

@